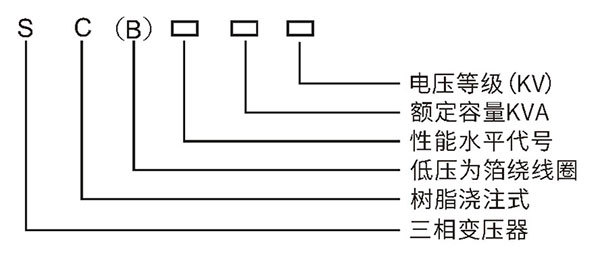

Model and meaning

Classification:

Key words:

Precious metal catalytic materials, special electrode materials, water treatment and environmental protection equipment

SCB10~SCB18 series epoxy resin cast dry-type transformers

Epoxy resin insulation dry-type transformer is our company introduced advanced technology at home and abroad, independent research and development of SC(B)10, SC(B)11, SC(B)12 and SC(B)13 series with filler thin insulation dry-type transformer.

Epoxy resin insulation dry-type transformer is our company introduced advanced technology at home and abroad, independent research and development of SC(B)10, SC(B)11, SC(B)12 and SC(B)13 series with filler thin insulation dry-type transformer. This series of transformers are made of high quality materials, scientific formula, and produced by advanced production and testing equipment and strict technology. The product has high reliability and long service life. According to different use environments, it can be configured with different protection levels or no housing. Widely used in power transmission and transformation systems, suitable for high-rise buildings, commercial centers, airports, tunnels, chemical plants, nuclear power plants, ships and other important or special environmental places.

Product Features

Since the coil is encapsulated by epoxy resin, it is difficult to burn, fire, explosion-proof, maintenance-free, pollution-free, small in size, and can be directly installed in the load center.

• Scientific and reasonable design and casting process make the product low partial discharge, low noise, strong mechanical power, strong short-circuit strength, good heat dissipation performance, and can increase the capacity by 50% under forced air cooling conditions.

• Equipped with intelligent temperature controller, with fault alarm, over-temperature alarm, over-temperature trip and black box function, and through the RS485 serial interface connected to the computer, can be centralized monitoring and control.

Product Structure

• Core

High-quality cold-rolled silicon steel sheet is selected, with a 5-level step structure of full oblique joint. The core column is bound with H-level non-weft adhesive tape, and the surface of the core is sealed with insulating resin to prevent moisture and rust, thus reducing no-load loss, no-load current and core noise. The surface of the upper iron yoke is painted with self-leveling measures to achieve smooth and bright, and the clip is a folded plate type, which is cut by laser, numerically controlled bending and pickling and plastic spraying. The weld seam of the clip is even and flat, and the appearance is smooth and transition, and the strength is full and atmospheric.

• High voltage winding

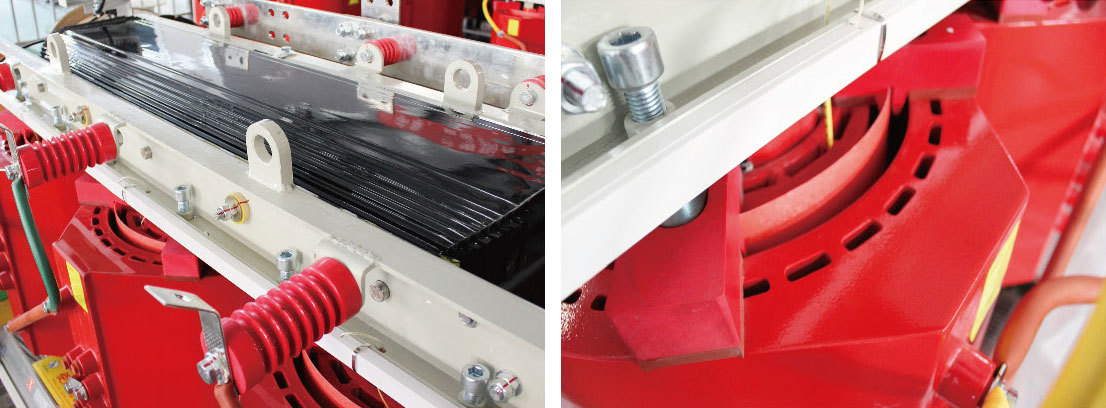

The windings are wound on a high-precision winding machine, and there are ventilation ducts when the capacity is large. The inner and outer walls of the windings are filled with glass fiber grid plates to enhance the mechanical strength of the coil. The high-pressure casting mold adopts a self-leveling structure to form a "gel glass surface" to ensure that the coil ends are flat and highly consistent. The mold material is required to be mirror stainless steel to ensure that the inner and outer surfaces of the coil are smooth and flat after pouring. Improve the ability of the product to resist sudden short circuit, and the coil will never crack.

• LV winding

The low-voltage winding adopts foil structure, which solves the problem of axial spiral angle when winding with wire, and makes the ampere turn more balanced. At the same time, the coil adopts axial cooling air duct, which enhances the heat dissipation capacity. DMD epoxy resin prepreg cloth is used between winding layers, and the whole is cured and formed.

• Manufacturing process

The resin mixed material adopts foreign advanced stirring method and vacuum film degassing technology, so that the mixture is evenly stirred and the bubbles in the middle of the mixture are completely eliminated. The coil is poured under vacuum pressure, the resin insulation has full encapsulation, and the layer turns are also completely permeable. The local discharge capacity of the product is controlled below 5PC. The casting body has a dense curing structure, flame retardant, explosion-proof, no pollution to the environment, so that the quality of the transformer made to achieve high quality.

• Temperature control system

The temperature controller uses the sensor (PT100) to collect the temperature signal of the transformer, and the intelligent controller monitors the temperature of the transformer coil, which improves the reliability of the system.

2. The anti-interference performance fully meets the requirements of JB/T7631 "resistance thermometer for transformer.

3. According to user needs to provide with computer interface and other functions of the thermostat.

4. Embedded installation, products with shell can be directly installed on the shell board, and products without shell can be installed on the transformer body or on the safety guardrail, which is simple, practical and convenient.

5. Common thermostat opening size 152X76 (length X width)

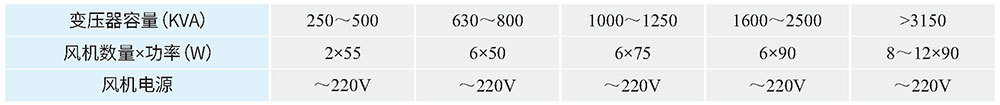

• Forced air cooling system

Dry-type transformer cooling methods are divided into natural air cooling (AN) and forced air cooling (AF).

2. When natural air cooling (AN), under normal use conditions, the transformer can continuously output 100% of the rated capacity.

3. When forced air cooling (AF), the cross-flow top-blown cooling fan is used. The cooling fan has the characteristics of low noise, high wind pressure and beautiful appearance. Under normal use conditions, the transformer can output 150% of the rated capacity. Suitable for all kinds of emergency overload or intermittent overload operation. Due to load losses and large impedance voltage increases, forced air cooling (AF) is not recommended for long-term continuous overload operation.

4. For transformers with natural air cooling (AN) and forced air cooling (AF), it is necessary to ensure that the transformer room has good ventilation capacity. When the transformer is installed in the basement or other environments with poor ventilation capacity, a heat dissipation ventilation device must be added. The ventilation volume is selected according to the air volume required for every 1KW loss (Po Pk) (3~4)m3/min.

5. The number of conventional capacity transformer fans, power and power supply configuration are as follows:

• Protective Enclosure

Protective shell for further safety protection of the transformer, the protection level is TP20, IP23, etc., the shell material is cold-rolled steel plate, stainless steel plate for users to choose.

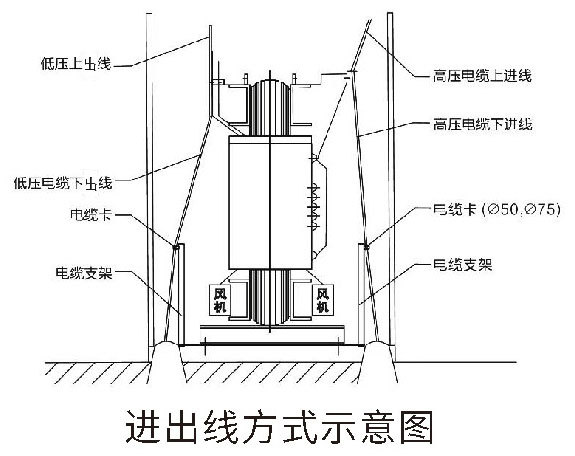

• Outlet mode of transformer

According to the different interface form manufacturing conventional outlet, standard enclosed bus and standard side outlet, can also be designed according to user requirements of special side outlet and other outlet way.

Related Products

S11~S22 series oil immersed transformers

A fully sealed transformer is a transformer that is completely isolated from the outside atmosphere inside the tank.

SCB10~SCB18 series epoxy resin cast dry-type transformers

Epoxy resin insulation dry-type transformer is our company introduced advanced technology at home and abroad, independent research and development of SC(B)10, SC(B)11, SC(B)12 and SC(B)13 series with filler thin insulation dry-type transformer.

immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!